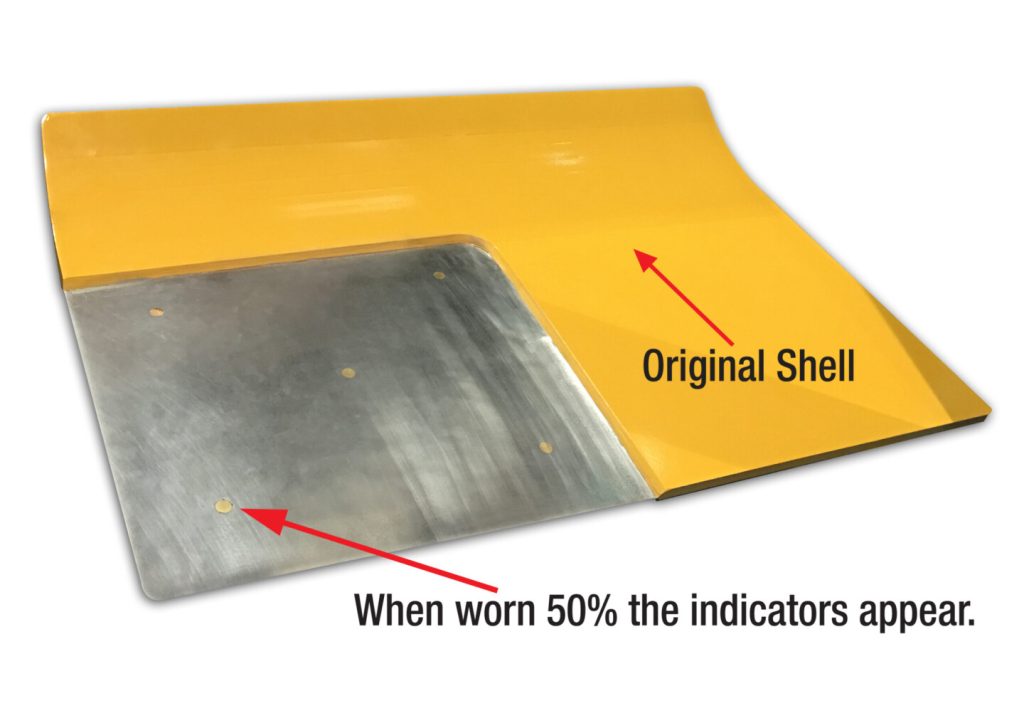

Wear parts equipped with Rockland Wear Pin technology (patent pending) allow operators to determine how much wear life remains in a part, just by looking at it.

When a moldboard, blade, liner or wear plate wears to a specific point, contrasting Wear Pins appear, signaling the need for maintenance or repair. The amount of wear over a certain period of time in a certain location, can also be easily determined, just by looking at the part.

We created this technology for two reasons:

- To prevent unscheduled downtime due to equipment failure by using a visual indicator of wear

- To eliminate the need for multiple manpower-intensive ultrasonic inspections

Simple Solution to a Long-Standing Problem

When the steel structure of a bucket or blade wears thin, cracks appear that may not be perceptible upon visual inspection. If the cracks aren’t properly repaired in a timely manner, they will continue to grow resulting in higher repair expenses and extended costly downtime.

To eliminate the need for continual ultrasonic inspections assessing the extent of cracks, the Wear Pins installed directly in the bucket shell, blade moldboard or any liner component during manufacturing become visible when the steel has worn to a point at which operators should schedule maintenance or prepare for replacement.

When buckets or blades wear thin and cracks start to occur, repairs can get costly, especially considering the potential loss of production. Unplanned downtime is the enemy of profitability for any equipment fleet and Rockland’s Wear Pin technology is a direct response to combat the unexpected.